Before learning about system windows, you will firstly need to learn about what are thermal break aluminum, aluminum alloy and uPVC windows.

Fifteen years ago, aluminum doors and windows became popular. They evolved from iron windows. Previous iron windows were prone to rust, deformation, and corrosion. The advantages of aluminum alloy include: resistance to corrosion and rust, safety and stability, as well as diverse color options.

3 years later, it was found that aluminum windows conducted heat and cold easily, but had poor thermal insulation. Then, we witched to uPVC windows made of plastic, which transfer heat and cold very slowly, and keep good insulation. However uPVC windows were found to be prone to deformation and posted significant safety hazards as time passed. Combining aluminum and uPVC windows-using aluminum for the exterior and plastic for the middle. With a series of optimizations, the hybrid design is known as thermal break aluminum windows.

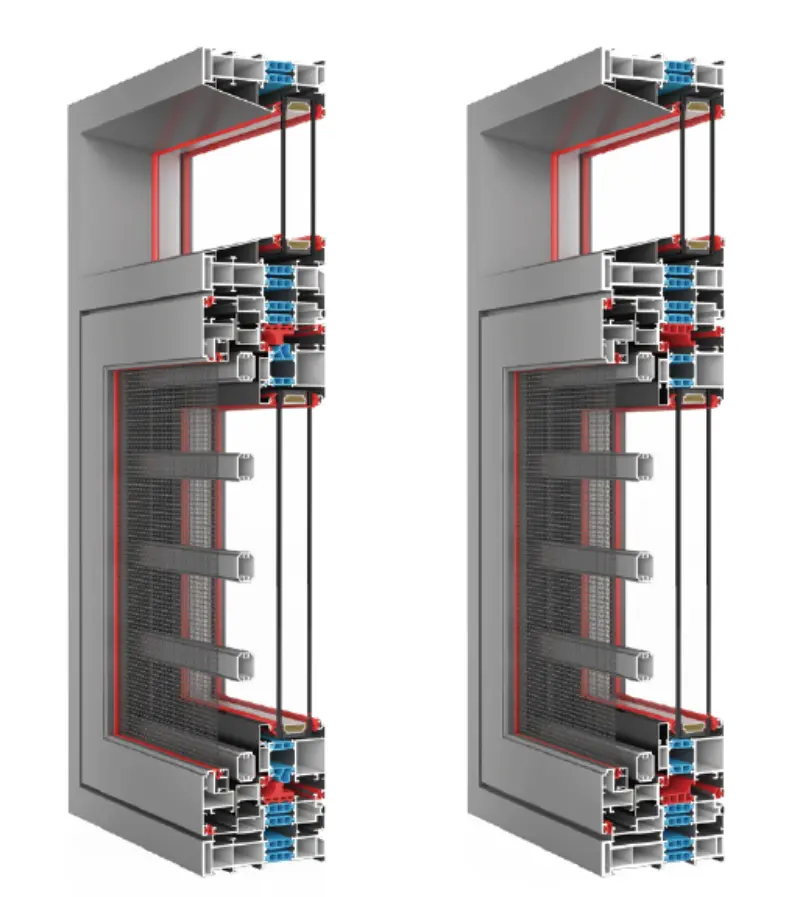

With the widespread application of thermal break aluminum windows, it was found that they inherited both the advantages of uPVC windows and some drawbacks of aluminum alloy—such as insufficient thermal insulation, inadequate soundproofing, and potential safety hazards. Through systematic upgrades, 90% of these issues have been resolved, and this optimized product is now known as system windows.

For homeowners with limited budgets, an alternative option was launched—windows with lower specifications that only address 50% of the core issues. These are known as semi-system windows or pseudo-system windows.

The 4 key differences between system windows and semi-system windows:

1) The glue injection is required for both corner brace and mullion. Corner brace glue injection resolves sash jamming cased by deformation. And mullion glue injection integrates the entire window into a single unit, enhancing wind pressure resistance and preventing water infiltration, which will ensure the requirements of safety, stability, water tightness and air tightness.

2) Hardware Upgrade

In the past, the hardware of thermal break aluminum doors and windows was highly prone to breakage and would tend to become stiff after years of use, making opening and closing difficult.

To address this: Modeled after anti-theft door hardware, we adopt lock-box type hidden hinges, which enhances the air tightness of the windows. By replacing traditional exposed hinges with sealed hinges, the product achieves better air tightness and thermal insulation—ensuring the entire sash remains in a sealed state at all times.

3)Vulcanized Welding for Weather stripping

By melting disconnected weatherstripping strips at high temperature, a seamless integrated piece is formed—with no gaps whatsoever. When the window is closed, it achieves a perfectly airtight seal. Currently, two other processes are available on the market: pin insertion process and one-piece bending process. However, both are prone to air or water leakage.

4)Use of 5mm+ Three-Layer Tempered Glass

This glass offers excellent safety, stability, and thermal insulation, along with effective soundproofing and temperature retention. In contrast, standard broken bridge aluminum windows typically use silver aluminum spacers, which are prone to condensation in winter. As a metal, aluminum has high thermal conductivity, causing the inner surface of the glass to become extremely cold and leading to condensation. After systematic upgrades, we adopt non-metallic fiberglass warm edge spacers, which maximumly resolves the condensation issue.

Recommendation

Invest in genuine system windows—they are designed for long-term use (10, 20, or even 30 years) without the need for replacement. While low-cost options (CNY300-500/㎡) may seem cost-effective initially, they often fail or become dysfunctional within 3-5 years. This is essentially a waste of social resources. If you are planning to replace your windows, system windows are a worthwhile consideration.