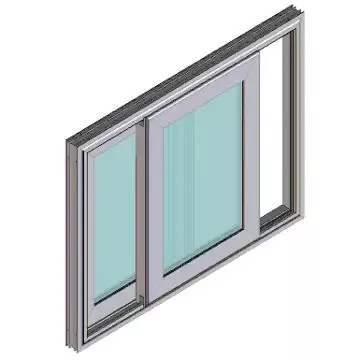

Aluminum glider windows are horizontally movable windows composed of aluminum alloy profile frames and track systems. The core of its cleaning is to deal with the deposition of pollutants on the sealing interface and moving parts. Scientific maintenance requires both surface finish and mechanical function protection.

The surface of the aluminum glider windows frame is made of aluminum alloy. Alkaline cleaners will destroy the crystal structure of the oxide film. The dust and metal debris accumulated in the track groove are mixed with grease to form a grinding paste, which aggravates the wear of the pulley. When the window sash is closed, the contact surface between the EPDM rubber strip and the glass is prone to residual water stains and crystals. Use a neutral pH solvent to wet the microfiber cloth and wipe it unidirectionally along the groove direction to avoid circular friction causing oxide layer moire. Remove the movable fan body before cleaning the track, remove the solid impurities in the base groove with a vacuum cleaner, and then clean the track sidewall with a non-woven fabric soaked in a low-viscosity solvent. The rubber strip groove uses a conical plastic scraper to guide the embedded objects to prevent metal tools from scratching the elastomer.

Double-layer insulating glass of aluminum glider windows should first be brushed off with a soft brush to remove particles from the frame to prevent scratches on the surface during the push-pull process. Cleaners should be scraped off immediately after being sprayed on the glass. If they are left on for too long, they will penetrate the sealant joints. Avoid working in direct sunlight. The temperature difference may cause the sudden cooling of the cleaner to cause stress cracks in the glass.

Anti-corrosion maintenance measures

After the track is dry, apply silicone-based grease, which does not react electrochemically with aluminum alloy. Rubber activator is applied regularly to the contact surface of the rubber strip to delay aging and maintain the compression rebound rate of the seal. The drainage holes of the window frame need to be cleared with a compressed air gun to prevent water accumulation and algae from clogging the channel.