a.Ordinary Series (50 - 70 Series)

Thickness: 1.2 - 1.4mm

Suitable for: Low - rise residential sliding windows

Representative model: 55 - series sliding windows (load - bearing capacity ≤40kg per square meter)

Market price: 280 - 380 RMB/㎡

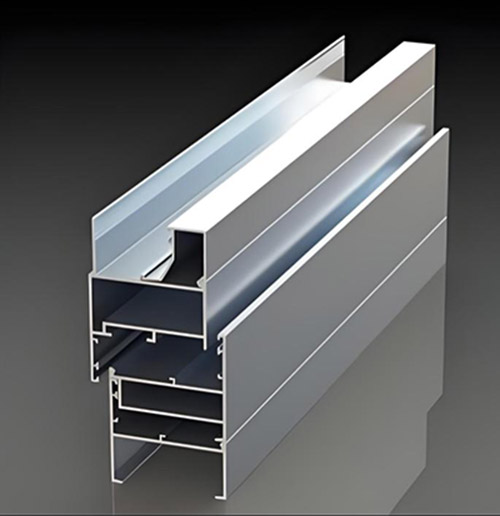

b.Broken Bridge Series (60 - 120 Series)

Features: Double - layer hollow structure + PA66 nylon thermal break strips

108 - series casement windows can resist category 12 typhoons

Recommended scenarios: Northern areas with central heating / houses facing busy streets

c.Heavy - Duty Sliding Series (90 - 120 Series)

Track width: Up to 9cm, with reinforced load - bearing beam design

Ideal for: Enclosing balconies with a span of over 3 meters

Typical application: Sunroom facade systems

1)First Generation: Ordinary Aluminum (1980s)

Drawbacks: Prone to deformation, high thermal conductivity (gradually phased out)

2)Second Generation: Electrophoretic Coating (2000s)

Surface hardness: Reaches 12μm, expanded color options

3)Third Generation: Wood Grain Transfer Printing (2010s)

Simulated solid wood texture accuracy: Up to 0.01mm level

4)Fourth Generation: Porcelain Coating Process (2020s)

UV resistance: Increased by 300%

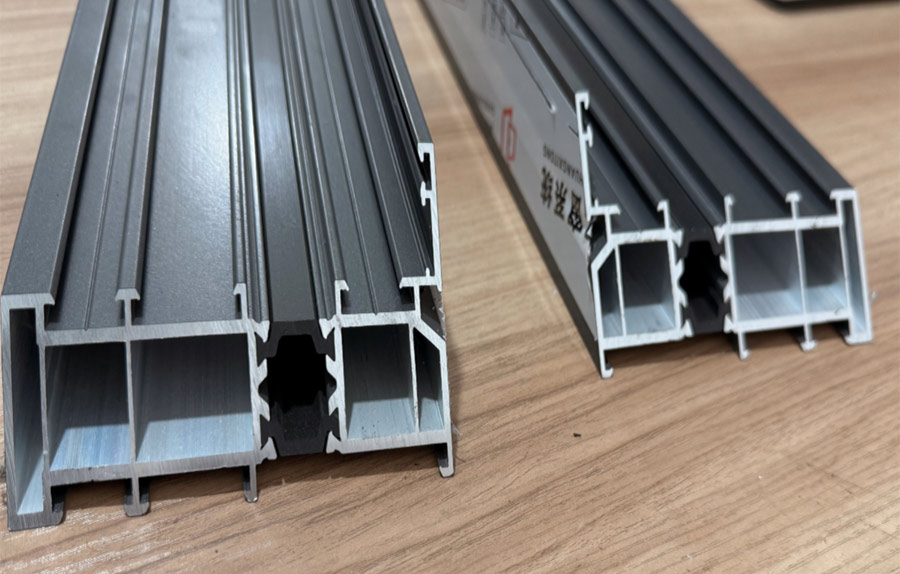

① Thickness Standards

National standard requirements: Exterior windows ≥1.8mm, interior doors ≥1.4mm

Detection tip: Use a magnet to identify genuine vs. fake broken bridge aluminum

② Thermal Insulation System

High - quality thermal break strips: Width ≥24mm

Warning: Beware of PVC imitating nylon materials

③ Surface Treatment

Performance ranking: Fluorocarbon spraying > Powder coating > Anodizing

Test method: Scratch with a coin - no obvious marks should appear

In summary, choosing windows and doors isn't about paying the highest price, instead it's about matching the aluminum profiles to your specific usage scenario. Selecting the right materials ensures both peace of mind and cost - effectiveness! As the professional manufacturer, Yingtai would like to provide you high quality Aluminum windows and doors, please get a quotation now!