1. Thermally-broken aluminum windows and doors

The core of aluminum windows and doors is the "thermally-broken" design, that is, adding insulation strips (usually PA66 nylon) to disconnect the aluminum alloy on both sides of the interior and exterior to form an effective thermal insulation barrier. This structure can significantly reduce heat conduction and improve thermal insulation performance. The thickness is usually between 1.4mm and 2.0mm, and the structure is relatively simple, mostly with two or three cavities.

2. System Windows and Doors

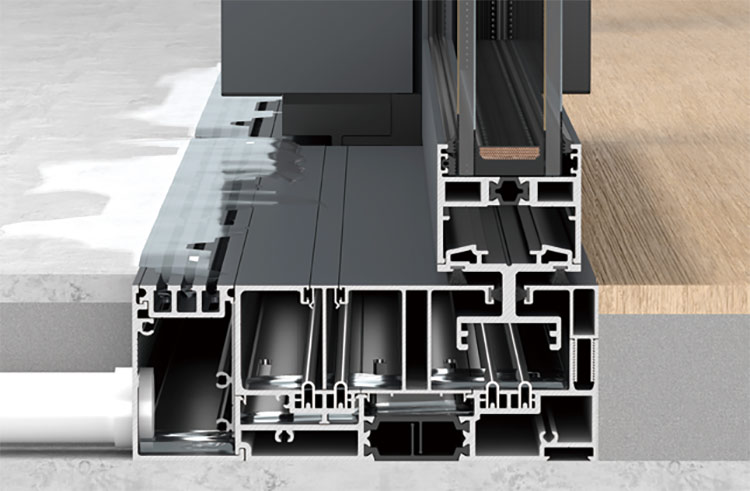

They are higher-end products, and their core lies in "systematic design". Except the basic material of thermally-broken aluminum, the profile structure, sealing system, hardware accessories, etc. are also optimized. The wall thickness is usually ≥1.8mm, the cavity structure is more complex (for example, a multi-cavity structure + isobaric drainage system design), and use automotive-grade sealing strips (such as EPDM) and imported hardware (such as Germany's Hobo).

1. Thermal insulation

The K value is generally 2.5-3.5 W/(㎡·K), which can meet the needs of ordinary families; while the system Windows and Doors can be as low as 1.0 or less through the multi-cavity design and Low-E glass, and the energy-saving effect is improved by more than 40%, which is more suitable for users in northern regions or those who are sensitive to energy consumption.

2. Sound insulation effect

Ordinary thermally-broken aluminum windows and doors can reduce noise by 25-35 dB, which is suitable for general urban environments; system Windows and Doors use laminated hollow glass (such as 5mm+0.76PVB+5mm) and multiple seals, and the noise reduction can reach more than 45 dB, which is the first choice for residential buildings near the street or airport.

3. Airtight and waterproof

The thermally-broken aluminum windows and doors mostly use two seals (strips + wool strips), and the water tightness is about 500Pa; the system Windows and Doors use more than three seals and hidden drainage design, and the water tightness can reach more than 700Pa, and the performance is better in typhoon-prone areas.

4. Wind pressure resistance

The system Windows and Doors have thicker profiles and strengthened middle stile design, and the wind pressure resistance level can reach 9 levels (the highest level of national standards), which is suitable for high-rise buildings; ordinary thermally-broken aluminum windows and doors are usually 6-7 levels.

1. Processing accuracy

The thermally-broken aluminum windows and doors are mostly on-site corner assembly (corner code + screw fixing), with an accuracy error of about ±1.5mm; the system Windows and Doors use a fully automated production line, and the corner assembly and glue injection process controls the error within ±0.5mm, and the overall stability is stronger.

2. Hardware system

System Windows and Doors are equipped with imported hardware as standard, and the number of opening times can reach more than 100,000 times, and support multi-point locking; ordinary thermally-insulated aluminum is mostly equipped with domestic hardware, and the service life is about 20,000 to 30,000 times.

3. Glass configuration

The thermally-insulated aluminum windows and doors usually use 5+12A+5 hollow glass; the system Windows and Doors can be upgraded to three-glass two-cavity (such as 5+9A+5+9A+5) or argon-filled glass, which has better insulation and sound insulation effects.

- Thermally-insulated aluminum windows and doors: The price is generally USD80-170/㎡(including installation), which is suitable for limited budgets or ordinary residences.

- System Windows and Doors: The unit price is usually USD200-420/㎡, and high-end products can reach more than USD700, which is more suitable for large houses, villas or energy-saving buildings.

P.S.: low-priced thermal break aluminum (<USD70/㎡) may use inferior insulation strips (PVC instead of PA66) or recycled aluminum. Pls check the profile section and test report when purchasing.