High-rise buildings have strict requirements on safety, durability, and wind resistance for aluminum doors and windows. Conformity to GB/T 8478-2020 is the essential prerequisite for compliance.

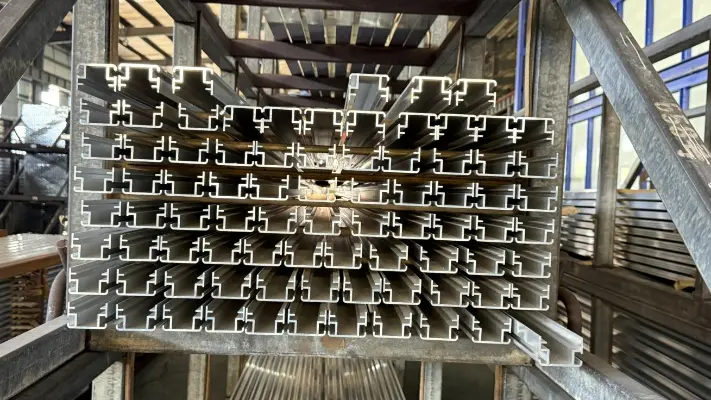

As a leading Chinese manufacturer for aluminum extrusion, we detail both the core requirements and our factory's quality assurance capabilities:

Wind pressure intensifies with building height, and profile thickness determines structural stability. In accordance with GB/T 8478-2020, Below are the specifications for different building floors:

11–20 floors: Recommended wall thickness: 1.8–2.5 mm; profile width: 108–120 mm

≥25 floors: Suggested wall thickness: 2.5–3.0 mm; profile width: 110–125 mm

Critical areas (e.g., slim-framed sliding doors, balcony windows): Minimum wall thickness ≥ 2.0 mm

Our automated production lines ensure precise control over wall thickness and dimensions, while the CNC precision machining center finishes critical components to enhance load-bearing capacity and wind resistance—making our profiles ideally suited for high-altitude applications.

The 6063 Aluminum profiles must achieve HW > 8 to ensure they resist deformation and damage under strong winds and impact.

Our upcoming CNAS-accredited laboratory will implement rigorous factory acceptance testing, guaranteeing 100% compliance of all profiles with the national standard and earning the trust of our global clients.

Based on 20 years of project experience, we recommend the following alloy tempers for optimal performance:

1) 6063-T5: Suitable for standard residential buildings under 6 stories, offering high cost-effectiveness.

2) 6063-T6: The preferred choice for high-rise structures and coastal areas, providing superior resistance to deformation and corrosion.

Our factory specializes in the production of 6063-T6 profiles, with advanced surface treatments further enhancing corrosion resistance. We also offer customized alloy temper solutions tailored to specific project requirements.

Mullion and transom reinforcement is critical for the structural safety of high-rise windows. Key requirements from national standards and specifications include:

l Reinforced mullions are required for window widths exceeding 1.8m or in typhoon prone regions.

l Mullion strength must increase with building height to counteract elevated wind loads.

Our CNC machining center custom manufactures reinforced mullions and transoms. Combined with 20 years of installation expertise, we ensure seamless integration with the window system for enhanced safety performance.

Choosing a manufacturer with proven capability is essential. We provide full chain support through:

l 20 Years of Specialization: End to end expertise covering production, fabrication, and installation.

l Hardcore Production Capacity: Automated lines and advanced equipment ensure volume output without compromising quality.

l Global Recognition: Products exported to 60+ countries with a mature international supply chain.

l Continuous Quality Advancement: Our upcoming CNAS accredited laboratory will reinforce whole process control.

l Customized Solutions: Tailored wind resistance designs and patented technologies compatible with multinational standards.

Why Partner with Us?

We build on national standards, leveraging industrial strength, global experience, and an unwavering commitment to quality. For overseas contractors, procurement teams, and developers, we deliver internationally compliant, customized solutions.

Contact us today to discuss your requirements. Let our two decades of specialized expertise safeguard your next project.